Textile Bleaching Wastewater Treatment Water Purification Equipment Electrocoagulation System Electrical Flocculation Coagulation Machine Water Treatment Plant

Description

Basic Info.

| Model NO. | QDEC-6 |

| Color | Grey/Silver/Blue/Balck/Customerized |

| Power | According to The Capacity or Customized |

| Material | Anti-Corrosion Carbon Steel or SS304 |

| Labor Cost | Low |

| Footprint | Small |

| Running Cost | Low |

| Operation | Auto Control PLC |

| Capacity | 1-1000m3 |

| Certification | ISO/CE/SGS/BV |

| Voltage | 220V/ 380V/ Customerized |

| Motor | German |

| Application | Wastewater Sewage Effluent Sludge Treatment |

| Water After Treated | Discharge / Recycle |

| Function | Remove Cod BOD Tss Color Heavy Metal |

| Transport Package | Standard Shipping Package |

| Specification | Based on the Flow Rate |

| Trademark | QDEVU or Customized |

| Origin | China |

| HS Code | 8421219990 |

| Production Capacity | 30/Month |

Product Description

Product DescriptionQDEVU Electrocoagulation(EC) Water Treatment PlantDescription

Electrocoagulation(EC) or Electrical Flocculation technology is a sewage treatment method that breaks the stable state of suspended solids, emulsified or dissolved pollutants in water by introducing direct current into the water. Compared with traditional chemical flocculation, electrical flocculation is an efficient and environmentally friendly water treatment technology without adding chemical or adding a small amount of flocculant, with low operation and maintenance cost, stable treatment effect and no secondary pollution of water quality and sediment.Electrocoagulation Dissolved Air Flotation (EC-DAF) Plant is a combination of electrolysis, flocculation and air flotation, which can remove all kinds of impurities in wastewater, like COD, BOD, oil,turbidity, suspended solid, biochemical degradation, heavy metal ions, chroma, calcium, magnesium ions,SiO2,colloidal silicon, organic silicon,bacteria and viruses,etc.

Working Principle

Electrocoagulation technology using electrochemical principle, such as aluminum, iron alloy as the main metal electrode, with the aid of function produce electrochemical reaction with high frequency dc power supply, to convert electrical energy into chemical energy, at the expense of the anode metal electrode produce metal cation flocculating agent, through condensation, in addition, reduction and oxidation decomposition of pollutants from water separation, the technique of purifying water body.

Functions

Electrocoagulation has four main functions: Electrolytic oxidationElectrolytic reductionElectrolytic flocculationElectrolytic flotationThree auxiliary functions:Sterilization, Decolorization, Deodorization.

Main Feature

• Low investment costs • Low operating costs • Low maintenance costs • No need to add any chemicals • Small footprint • Simple operation, high degree of automation • Short processing time and high processing efficiency • Adapt to a wide range of wastewater, can treat a variety of pollutants • Equipment treatment produces less sludge, high density of sludge

Application

Electrocoagulation can be widely used in many wastewater treatment industries. Such as electroplating wastewater, washing wastewater, and textile bleaching wastewater, paper mill wastewater, slaughter wastewater, waste water, food and beverage manufacturers oil refinery wastewater, oil field wastewater, pharmaceutical wastewater, mining wastewater, waste leachate wastewater, agricultural wastewater, paint dye, pigment, such as waste water, waste water cooling towers, wood processing waste water, the traveling scenic area sanitary sewage, It can also be used for sewage purification at the bottom of the ship and port catchment area.

1. Compared with filtration, membrane separation, UV disinfection process, the application of a wide range of high processing efficiency, processing diverse objects.2. 96% of the ozone utilization rate, saving the cost of ozone equipment for disinfection.3. Removal of organic matter, phosphide, kill pathogens, bleaching and other treatment effect is good.4. Particularly suitable for the treatment of wastewater containing difficult to decompose substances.

Differences between Electrocoagulation and Traditional process

| Process | Air flotation | Flocculation | Oxidation | Reduction |

| Main Function | Oil RemovalDecolorizingSS RemovalPretreatment | DecolorizingSS RemovalPretreatment | PretreatmentDeep treatmentBreak complex forming | Pretreatment |

| Traditional Process | Ordinary air flotationThe bubble is larger, and the removal effect of tiny oil particles and suspended matter is poor, so it needs to add agents, and the organic pigment can hardly be removed | Dosing flocculationDosage needs to be adjusted according to the different water quality, the sludge production is large, the drug cost is high, the treatment effect is unstable, almost can not remove organic pigment | Oxidant oxidationLow oxidation rate, dosage changes with water quality, not easy to adjust, high pharmaceutical costs | Reduction with reducing agentThe reduction rate is low, the dosage changes with the water quality, it is not easy to adjust, and the drug cost is high |

| Electrochemistry | The bubbles produced are tiny and can remove pollutants from tiny particles without the need to add additional agents. | There is no need to add flocculant, and the change of water quality has little influence on the treatment effect. The treatment effect is stable and the sludge production is small. | Without adding oxidant, the oxidation efficiency is high, the breaking of the collateral is more than 99%, and the effluent B/C is more than 0.35 stable. | The reduction rate is above 99.5% without adding reducing agent |

| Application | Floating oil waste waterThe desulfurization wastewaterPapermaking wastewaterCoal chemical wastewaterPetrochemical wastewater | Printing and dyeing wastewaterPharmaceutical wastewater | RO concentrated water treatmentCoke copper wastewaterElectroless nickel plating wastewaterWastewater containing complex compoundsHigh concentration wastewater | Chromium plating wastewater |

Our Company

Qingdao EVU Environmental and Engineering Equipment Co., Ltd. is established in 1999,it is one of scientific research design, equipment manufacture, installation, commissioning and training services as one integrated technology-oriented enterprises in water treatment industry. It is holding by Qingdao Spark Textile Machine Co., Ltd which is a national Spark Industrial Group, national second-level and large-scale comprehensive enterprise group in China.Our Products

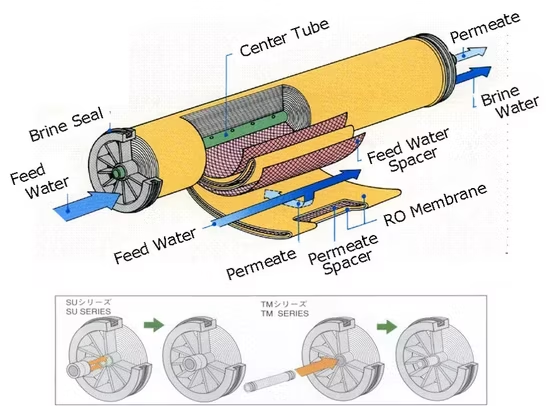

We use the advanced technology and equipment over the world. Our main productions: Integrated Sewage Treatment Equipment, MBR Sewage Treatment Equipment(MBR), Electrocoagulation Sewage Treatment Plant(EC Plant), Reverse Osmosis Filteration Equipment(RO System), Dissolved Air Flotation Machine(DAF), Cavitation air Flotation Machine(CAF), Aerator, Screw Press Sludge Dewatering Machine, Automatic Chemical Dissolved and Dosing machine, Sludge Scraper, Slag Scraper, The micro bubble generator, USAB anaerobic reactor, Bar Screen, Sand Filter and so on series products.Our Customers

We have professional engineer support, high efficiency sales team and competitive price superiority, and attract customers from all over the world, we export to over 40 countries, including Europe, Poland, Serbia, Uruguay, Turkey, Russia, USA, Mexico, Brazil, Singapore, India, Egypt, Thailand, Middle east and South Africa.Our Certificate

We based on "technological development, pollution remediation, wholeheartedly for customer services". We hope to cooperate with all customers from all over the world and build a better world together.FAQQ1:Are you a factory or trading company?

We are a real manufacturer who can offer you both the most competitive price and top quality products.

Q2:Where is your factory located? How can I visit there?

Our factory is located in Qingdao City Shandong Province, All our clients, from home or abroad, are warmly welcome to visit us!

Q3:Can you put my company brand (logo) on the products?

Yes,we support OEM/ODM service,the customize process as follows:1.Customers put forward personalized customization requirements.2.Our engineer draw the design draft.3.Customer confirm the design draft.4.Factory start to produce shipment.

Q4:How to select right model?

You can tell us what you need, and we can help you choose the Model.Basic informations as follows:Wastewater type : Industry wastewater, Domestic wastewater, food wastewater or others)Capacity:m³/Day or m³/Hour?Raw water quality: SS, Oil & Grease &Fat & FOG, PH,BOD,COD content?Output water quality standard,for discharge or reuse?Local voltage and frequency?

Q5: What is your MOQ?

Normally, our MOQ is 1 set.

Q6:What is the payment term ?

TT and L/C are acceptable and TT will be more appreciated, 30% deposit, 70% balance payment before shipment.

Q7: We haven't imported before, can you ship the goods to our warehouse?

Yes. Although our normal trade term is EXW, FOB, CIF, we can also arrange logistics to your warehouse.

Q8:What is the delivery time of your factory?

5-10 days for general series products, meanwhile, batches products & customized products would need 15-30 days based on different situations.Contact us for the exact time.

Q9:How do you ensure the quality of your products?

Generally, our equipment are the most durable type in the industry, this is also the feature of the label impression for most of our customers at home or abroad.Skilled workers and strict quality control system can ensure every machine with best working performance.

Q10:How to assemble the equipment once we received it?

The CAD install instruction, assembly procedure and project case will be provided.,Of course our skilled installation engineers would go to your country and install the equipment if needed.

Q11: What is your product warranty ?After sales service?

The warranty is 12 months while the lifetime is 10-15 years under good maintenance.It is durable and anti-corrosion.Provide equipment certification and installation operating instructions.Provide one-year spare parts.Provide technical advisory services.Provide guidance staff for installation and commissioning.

Our Contact