RO Membrane Element for Reverse Osmosis Membrane BW30 400 Equivalent

Description

Basic Info.

| Model NO. | TFBW-8040 |

| Equivalent | BW30-400 |

| Minimum Salt Rejection | 99.4% |

| Stabilized Salt Rejection | 99.6% |

| Membrane Material | Polyamide Thin-Film Composite |

| Diameter | 201 mm |

| Length | 1016 mm |

| Size | 8040 |

| Membrane Active Area | 37.2 M2 |

| Series | Brackish Water |

| Transport Package | Paper Carton |

| Specification | 107*20.5*26 cm |

| Trademark | Tanal |

| Origin | China |

| HS Code | 8421999090 |

| Production Capacity | 80000 Pieces/Year |

Product Description

Product Description

General Information

TFBW-8040 is manufactured as an equivalent for BW30-400 (BW30400) RO (reverse osmosis) membrane.

TFBW-8040 reverse osmosis membrane elements are developed for brackish water treatment, ideal for reverse osmosis plant managers and operators dealing with brackish water with pre-treatment.

This reverse osmosis membrane element provides consistency, high permeate water quality, high performance and productivity, and long service life.

Features & Advantages

- Provides high-quality permeate water

- Stable salt rejection rate and high permeate flow rate

- Optimized design, good resistance to fouling results in long service life

- High chemical tolerance for cleaning with highly effective cleaning performance

- Simple and economical element replacement

Applications

- Industrial pure water

- Industrial wastewater reuse

- Slightly contaminated water etc.

Specifications

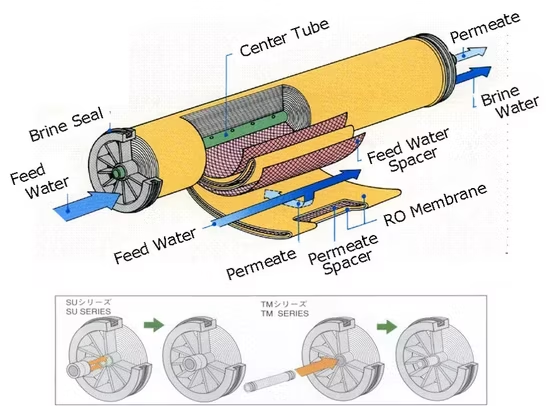

- Configuration: Spiral wound element

- Membrane Polymer: Polyamide thin-film composite

Performance

| Element Model | Membrane Active Area ft2 (m2) | Feed Spacer mil (mm) | Permeate Flow Rate*GPD (m3/d) | Stabilized Salt Rejection** | Minimum Salt Rejection |

| TFBW-8040 | 400 (37.2) | 28 (0.712) | 10,500 (39.7) | 99.6% | 99.4% |

Standard test conditions:

The above performance is initial(data record after 30 minutes of operation), based on the following conditions:

2,000 ppm NaCl solution

225 psi (15.5 bar) operating pressure

25°C (77°F) operating temperature

15% permeate recovery

7.5-8 pH range

*Permeate flow for individual elements may vary but will be no more than ±15%.

**Stabilized salt rejection is generally achieved within 24-48 hours of continuous use; depending on feed water characteristics and operating conditions.

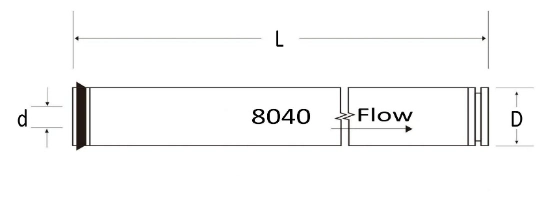

Element Dimensions

| Length Linch (mm) | Diameter Dinch (mm) | Permeate tube inner diameter dinch (mm) |

| 40 (1,016) | 7.9 (201) | 1.125 (28.6) |

Operating and Cleaning Limits

| Maximum Operating Pressure | 600 psi (41 bar) |

| Maximum Operating Temperature | 45°C (113°F) |

| Maximum Chlorine Concentration | 0.1 ppm |

| pH Range, Continuous | 2-11 |

| pH Range, Cleaning | 1-13 |

| Maximum Feed SDI (15 mins) | 5 |

| Maximum Element Pressure Drop | 15 psi (1 bar) |

| Maximum Feed Flow | 17 m3/h |

| Minimum Ratio of Concentrate to Permeate Flow for Each Element | 5:1 |

The limits shown above are for general applications. For specific projects, operating at more conservative values may ensure the best performance and longest life of the membrane element.

CertificationsISO 9001:2015 Quality Management Systems Certificate

TÜV Audit Certificate

Export License

1. Customer-centric company culture

2. Efficient and flexible organizational system

3. 20+ years experience in membrane research, development and manufacturing

4. Better cost-effectiveness

1. Warranty granted.

2. Remote technical training, guidance and support.

3. On-site technical support for training, installation, commissioning, operation and trouble shooting.

4. Free replacement in warranty period.

Feedback Handling Process as below:

Picking up the phone and having the plant manager yelling at you about undelivered membranes and filters?

Your customers are complaining to you about the high costs of existing membranes and filters?

Feel frustrated in prices when you are bidding?

Send your inquiry to us and get a quote for your project now!

Our Contact